GST No- 27AAAFF0424D1Z5

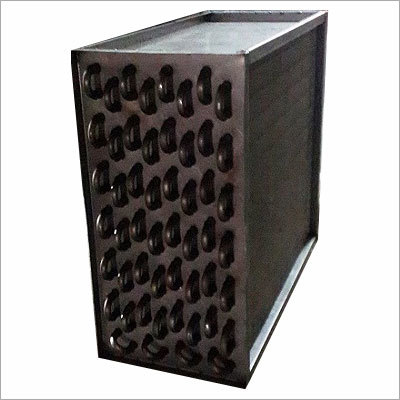

Marine Heat Exchanger

50000 INR/Piece

Product Details:

- Condition New

- Usage Industrial

- Size Standard

- Voltage 220 Volt (v)

- Product Type Marine Heat Exchanger

- Color Grey

- Click to View more

X

Marine Heat Exchanger Price And Quantity

- 01 Piece

- 50000 INR/Piece

Marine Heat Exchanger Product Specifications

- New

- Industrial

- 220 Volt (v)

- Marine Heat Exchanger

- Standard

- Grey

Marine Heat Exchanger Trade Information

- 100 Piece Per Month

- 5-7 Days

- Yes

- Within a certain price range free samples are available

- Carton BoxesBoxes

- Australia, Eastern Europe, Middle East, Western Europe, Africa, Central America, South America, Asia, North America

- All India

Product Description

Since our inception, we are instrumental in manufacturing and supplying a premium quality range of Marine Heat Exchanger. Provided exchanger is widely used in various industries like plastic, rubber, paper, chemical and fertilizers for heating and cooling proposes. These exchangers are manufactured under the guidance of our adroit engineers by using latest technologies as per the set international norms. Owing to features such as less power consumption, sturdy design, and durable service life and made with top quality products is highly demanded by our precious customers. Our offered Marine Heat Exchanger is available in the market at affordable prices.

Versatile Industrial Solution

Our Marine Heat Exchanger is tailored for diverse marine and industrial operations, providing seamless thermal transfer and energy efficiency. Its standard size and 220 Volt configuration make it universally compatible with a wide variety of installation requirements. Trusted by companies in India for export, import, manufacturing, and distribution, this grey heat exchanger is built to deliver consistent results and long service life.

Built for Reliability

Manufactured with high-grade materials, the Marine Heat Exchanger is developed to withstand the demanding conditions of industrial environments. Featuring a robust construction and precision design, it maintains optimal performance while minimizing maintenance needs. This ensures a safe, efficient, and cost-effective solution for all thermal management needs.

FAQs of Marine Heat Exchanger:

Q: How is the Marine Heat Exchanger installed in industrial settings?

A: The Marine Heat Exchanger is provided in a standard size with a 220 Volt configuration, simplifying installation in existing industrial setups. Detailed instructions from the manufacturer guide the proper connection and integration based on your systems requirements.Q: What benefits does the Marine Heat Exchanger offer for marine and industrial usage?

A: This heat exchanger provides efficient temperature control, improved operational reliability, and reduced energy consumption. Its robust design ensures durability and minimizes maintenance, making it an advantageous investment for industrial and marine applications.Q: When should the Marine Heat Exchanger be serviced or maintained?

A: Routine maintenance is recommended based on usage intensitytypically every 6 to 12 months for industrial environments. Regular inspection supports prolonged efficiency and prevents any potential downtime.Q: Where can I purchase or source the Marine Heat Exchanger in India?

A: The Marine Heat Exchanger is available through authorized manufacturers, distributors, exporters, importers, suppliers, and traders throughout India. You can contact these providers directly or via their websites for quotations and details.Q: What is the process for procuring the Marine Heat Exchanger as an exporter or importer?

A: Exporters and importers can place bulk or customized orders with the manufacturing or supplying companies in India. The process typically involves quotation requests, order confirmation, quality checks, and timely shipment arrangements.Q: How should the Marine Heat Exchanger be used in industrial applications?

A: It should be installed within the facilitys thermal management system, following the manufacturers usage guidelines. Ensure the unit operates within its electrical requirements (220 Volt) for optimal performance and safety.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese