GST No- 27AAAFF0424D1Z5

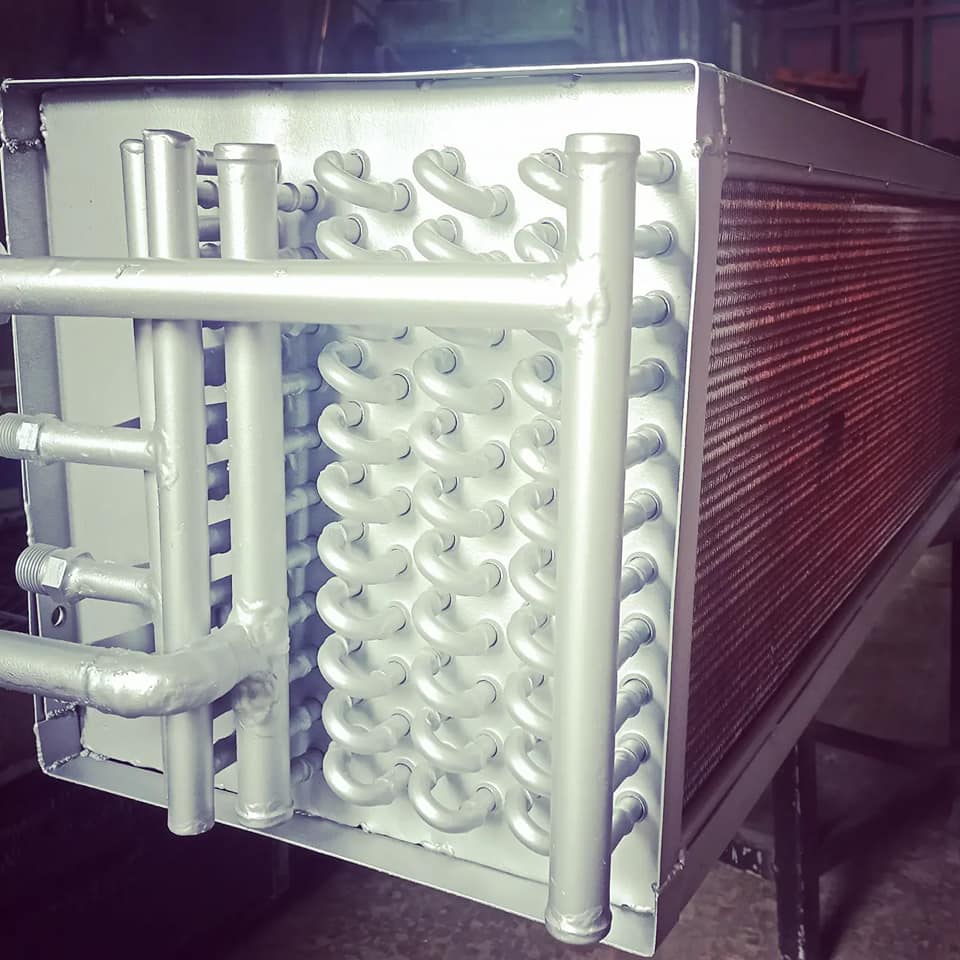

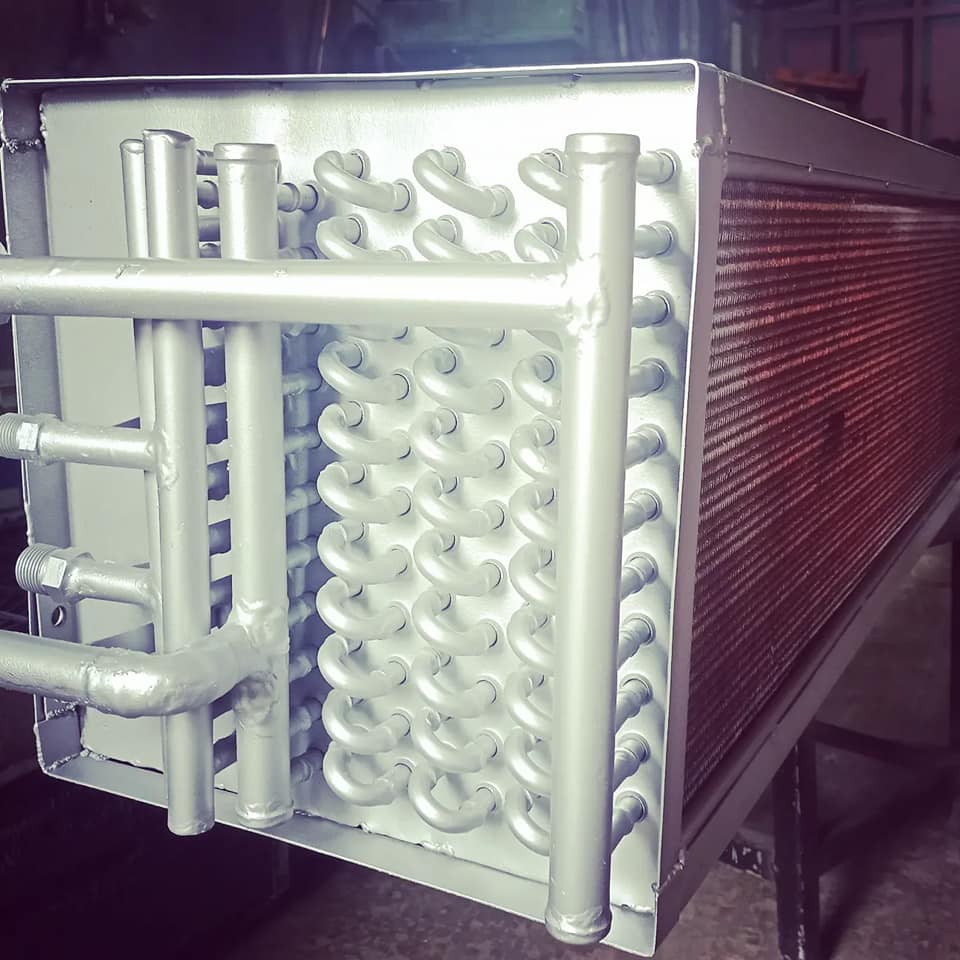

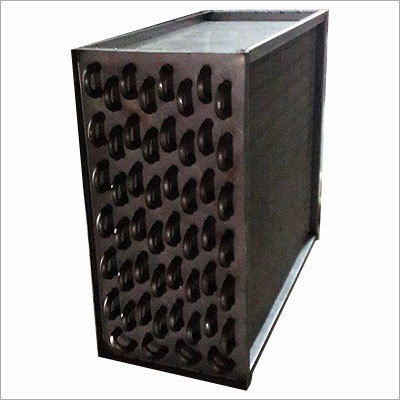

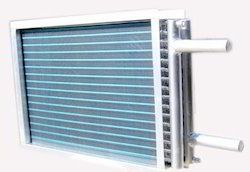

dx Cooling Coils

10000.0 INR/Unit

Product Details:

- Usage Industrial

- Size Standard

- Product Type dx Cooling Coils

- Hardness rIGID

- Application Industrial

- Warranty 1 Year

- Click to View more

X

dx Cooling Coils Price And Quantity

- 1 Unit

- 10000.0 INR/Unit

dx Cooling Coils Product Specifications

- Industrial

- dx Cooling Coils

- Standard

- 1 Year

- Industrial

- rIGID

dx Cooling Coils Trade Information

- Cash Advance (CA)

- 100 Unit Per Month

- 7 Days

- WOODEN

- All India

- TEST CERTIFICATE

Product Description

DX Cooling Coil Basic Technical Specifications

| Parameter | Typical Values / Notes |

|---|---|

| Coil Type | Direct Expansion (DX), fin-tube type |

| Refrigerant Type | R-410A, R-22, R-407C, R-32 (depends on system) |

| Material (Tubes) | Copper (standard), or SS304 for corrosive applications |

| Material (Fins) | Aluminum (standard), hydrophilic coated optional |

| No. of Rows | 2 to 8 rows (depends on required capacity) |

| Fin Density | 8 14 fins/inch |

| Tube Size (OD) | 3/8", 1/2", or 5/8" |

| Tube Thickness | 0.28 0.38 mm (standard) |

| Fin Thickness | 0.1 0.15 mm (standard) |

| Face Area | Varies (e.g., 600 x 400 mm to 1200 x 1000 mm or more) |

| Refrigerant Inlet/Outlet | Copper stub with flare/nut, or sweat connection |

| Air Flow Direction | Horizontal or vertical (coil orientation-dependent) |

| Design Air Velocity | Typically 2.5 3.0 m/s (500 600 FPM) |

| Face Velocity Limit | 2.5 m/s (for dehumidification and coil efficiency) |

| Cooling Capacity | Ranges from 5 kW to 100+ kW depending on design |

| Drain Pan | Galvanized or stainless steel, sloped for drainage |

| Working Pressure | 300450 psi (varies by refrigerant) |

| Test Pressure | 500 psi (leak test under nitrogen) |

Engineered for Industrial Performance

Our DX Cooling Coils are crafted using advanced manufacturing techniques to deliver reliable performance in industrial environments. Their rigid construction ensures longevity and consistent efficiency, making them the preferred choice for factories, warehouses, and processing units requiring robust cooling systems.

Comprehensive Services and Supply Network

As a manufacturer, supplier, and service provider, we cover the full spectrum of DX Cooling Coil distribution across India. Whether you need installation, maintenance, or custom solutions, our expert network supports your cooling requirements promptly and effectively.

FAQs of dx Cooling Coils:

Q: How are DX Cooling Coils used in industrial settings?

A: DX Cooling Coils are integrated into industrial air conditioning systems to regulate temperature and maintain optimal environmental conditions for machinery and personnel. Their standard size and rigid design make them suitable for various large-scale applications.Q: What benefits do DX Cooling Coils offer manufacturers and suppliers?

A: Manufacturers and suppliers experience improved energy efficiency, reduced downtime, and longer equipment lifespans thanks to the reliable cooling performance and durable construction of DX Cooling Coils.Q: When should DX Cooling Coils be replaced or serviced?

A: Regular inspection and servicing are recommended annually. Coils should be replaced if efficiency drops, visible wear occurs, or after reaching the end of their warranty period to ensure continued optimal functioning.Q: Where can DX Cooling Coils be sourced in India?

A: DX Cooling Coils are readily available through authorized distributors, exporters, importers, manufacturers, service providers, suppliers, and traders throughout India, ensuring quick access for industrial clients.Q: What is the process for installing DX Cooling Coils in an industrial setup?

A: Installation involves integrating the coils into existing HVAC systems, ensuring proper connection to refrigerant lines and air handlers. Qualified professionals handle setup and testing to meet safety and performance standards.Q: How does the rigid hardness of these coils contribute to their industrial use?

A: The rigid construction enhances durability, supporting continuous operation in demanding environments where mechanical strength and reliability are essential for effective cooling.Q: What warranty is provided with DX Cooling Coils?

A: Each DX Cooling Coil comes with a 1-year warranty, covering manufacturing defects and ensuring peace of mind for industrial users.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese