GST No- 27AAAFF0424D1Z5

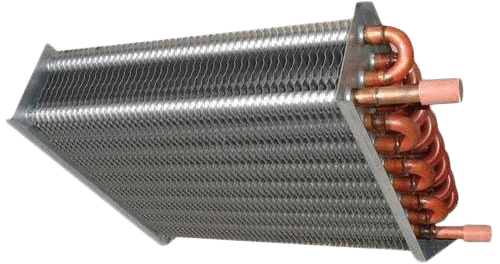

Heat Exchangers

5900 INR/Piece

Product Details:

- Usage Industrial

- Condition New

- Structure tube Heat Exchanger

- Size Standard

- Voltage 220 Volt (v)

- Color Grey

- Click to View more

X

Heat Exchangers Price And Quantity

- 5900 INR/Piece

- 1 Piece

Heat Exchangers Product Specifications

- 220 Volt (v)

- tube Heat Exchanger

- Standard

- Grey

- Industrial

- New

Heat Exchangers Trade Information

- 1000 Piece Per Week

- 7 Days

- Yes

- Within a certain price range free samples are available

- Carton BoxesBoxes

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

We are an eminent name, engaged in manufacturing and supplying our precious clients a superior quality range of Heat Exchanger. Provided exchanger is widely used in air conditioning, power plants, refrigeration and chemical plants for heat transfer from one medium to another. This exchanger is manufactured in compliance with international standards under the guidance of our professionals or rigorously tested on various quality parameters. Offered exchanger is highly appreciated by our customers due to their hassle-free functionality, sturdy construction, low power consumption and long serviced life. Our offered Heat Exchanger can be availed from us at industry-leading prices.

Robust Industrial Solution

The tube heat exchanger is a versatile solution for various industrial sectors. Its grey finish and standard size make it easy to integrate into existing systems. Built to operate at 220 Volt, it ensures compatible and reliable performance in Indian industrial settings. Perfectly suited for heating, cooling, and other thermal management processes.

Functional Design for Efficiency

The tube structure maximizes surface area, which leads to more efficient heat transfer between fluids. Whether implemented in manufacturing, processing, or energy facilities, this heat exchanger supports seamless temperature control and boosted process reliability. All units are delivered new and ready for rapid deployment.

FAQs of Heat Exchangers:

Q: How is the tube heat exchanger utilized in industrial applications?

A: The tube heat exchanger is used for transferring heat between two fluids in industries such as chemical processing, power generation, and manufacturing. Its tubular design allows efficient thermal exchange, making it ideal for heating or cooling fluids during production cycles.Q: What are the benefits of choosing a standard, grey tube heat exchanger?

A: Choosing a standard, grey tube heat exchanger ensures easy integration, reliable performance, and robust durability. The standardized size simplifies installation, the grey color offers a neutral industrial look, and its construction supports high efficiency and longevity in demanding industrial environments.Q: When should a new tube heat exchanger be considered for industrial use?

A: A new tube heat exchanger should be considered when upgrading outdated equipment, enhancing energy efficiency, or expanding capacity within existing systems. It is also recommended when existing exchangers are showing signs of wear or no longer meet regulatory or operational requirements.Q: Where are these heat exchangers commonly distributed and supplied in India?

A: Our tube heat exchangers are distributed and supplied across various industrial hubs in India, catering to sectors such as chemical plants, energy facilities, food processing units, and more. As both supplier and service provider, we address pan-India requirements.Q: What is the process for installing a standard tube heat exchanger?

A: Installation involves integrating the heat exchanger into the industrial pipeline, ensuring proper alignment and electrical connection to a 220 Volt power source. Our service team assists with installation, commissioning, and provides guidelines for safe and efficient operation.Q: How does a tube heat exchanger improve operational efficiency?

A: The design promotes optimal heat transfer and temperature regulation, which helps industrial processes run more efficiently. This reduces energy consumption, minimizes downtime, and prolongs the service life of associated equipment.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese